In material handling, safety is paramount, and innovations like the Yale Toss Sensor make it possible to combine efficiency with accident prevention. Specifically designed for forklifts like the GLP050VX model, this sensor plays a vital role in ensuring safe operations. If you’ve been wondering about the Yale Toss Sensor location GLP050VX, this guide will cover everything you need to know about its placement, functionality, and benefits.

Let’s dive into the details to ensure you make the most out of this essential forklift feature.

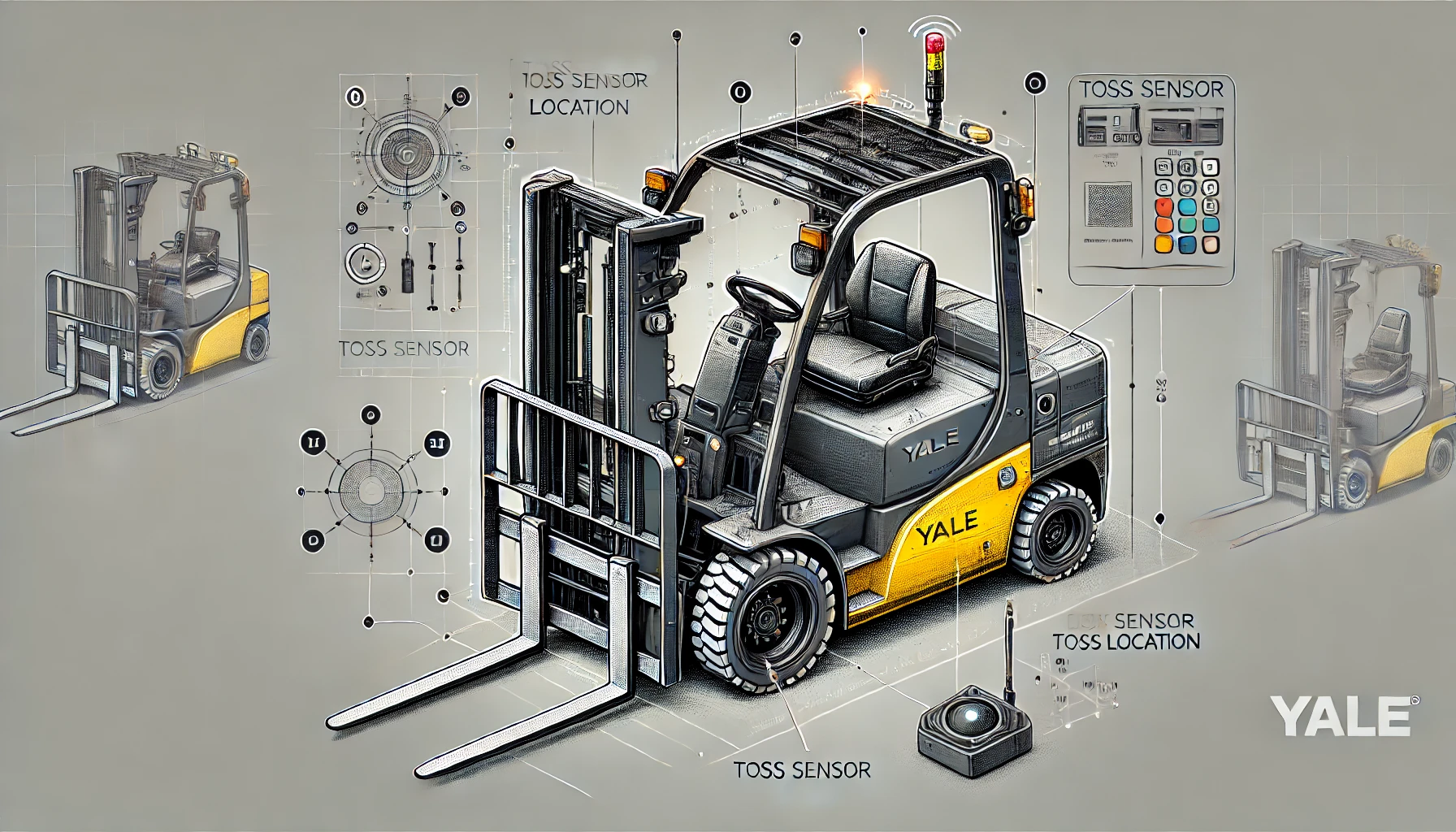

Where is the Yale Toss Sensor Located on the GLP050VX Forklift?

Understanding the Yale Toss Sensor location GLP050VX is crucial for proper installation and maintenance. This sensor is typically positioned near the mast or the lifting mechanism of the forklift. This strategic location allows the sensor to effectively monitor the tilt and alignment of the forks in real time.

Forklift operators should always refer to the user manual for a precise understanding of where the sensor is installed. Knowing the Yale Toss Sensor location GLP050VX helps ensure regular maintenance and prompt troubleshooting, ensuring that the equipment operates optimally.

How Does the Yale Toss Sensor Work?

The Yale Toss Sensor location GLP050VX is carefully designed to support safety by detecting the tilt angle of the forks and monitoring load stability. Using advanced accelerometers and gyroscopic technology, the sensor collects data on the movement and alignment of the forks.

This constant monitoring allows the sensor to trigger alerts if it detects excessive tilt or an unstable load. With the Yale Toss Sensor location GLP050VX optimized for efficiency, operators can make real-time adjustments to avoid accidents. By integrating seamlessly with existing forklift systems, the sensor ensures smooth, uninterrupted operations.

Benefits of Using the Yale Toss Sensor in Material Handling

The Yale Toss Sensor location GLP050VX is an essential feature for any workplace prioritizing safety and efficiency. Here are the key benefits:

- Enhanced Safety: The sensor significantly reduces tipping hazards by monitoring and alerting operators of unsafe angles.

- Efficiency in Operations: With accurate and real-time feedback, operators can handle materials more confidently.

- Cost Savings: Businesses benefit from fewer accidents, which means less downtime and reduced repair costs.

- Insurance Perks: Investing in safety features like the Yale Toss Sensor location GLP050VX often leads to lower insurance premiums.

- Compliance with Safety Standards: Many industries require advanced safety features, and this sensor ensures compliance.

The Yale Toss Sensor location GLP050VX not only ensures operational efficiency but also fosters a culture of safety.

Common Issues and Troubleshooting Tips

Despite its advanced design, the Yale Toss Sensor location GLP050VX can occasionally experience issues. Below are some common problems and how to fix them:

- Inaccurate Readings:

- Solution: Recalibrate the sensor and check for loose connections.

- Dust or Dirt Build-Up:

- Solution: Clean the sensor regularly to ensure proper functionality.

- Physical Damage:

- Solution: Inspect for cracks or breaks. Replace damaged parts immediately.

- Software Glitches:

- Solution: Ensure the software associated with the Yale Toss Sensor location GLP050VX is up-to-date.

Regular troubleshooting and proactive maintenance can ensure the Yale Toss Sensor location GLP050VX operates at its best.

Proper Installation and Maintenance Guide

For maximum efficiency, the Yale Toss Sensor location GLP050VX must be correctly installed and maintained.

Installation:

- Choose the Right Location: Follow the user manual to confirm the precise Yale Toss Sensor location GLP050VX.

- Secure Placement: Ensure the sensor is firmly attached to prevent movement during forklift operations.

- Test After Installation: Validate the sensor’s performance through tests to ensure accuracy.

Maintenance:

- Routine Inspections: Check the Yale Toss Sensor location GLP050VX for wear, loose connections, or debris.

- Cleaning: Keep the sensor clean to avoid interference from dirt or grime.

- Software Updates: Regularly update the system to optimize performance.

- Documentation: Maintain a log of all activities related to the Yale Toss Sensor location GLP050VX for reference and compliance.

How to Optimize Forklift Performance with the Yale Toss Sensor

To fully leverage the Yale Toss Sensor location GLP050VX, operators and businesses should consider the following strategies:

- Operator Training: Ensure forklift operators understand how the sensor works and how to respond to alerts.

- Routine Maintenance: Regularly inspect the Yale Toss Sensor location GLP050VX to ensure it’s functioning correctly.

- Data Review: Analyze sensor feedback to improve handling techniques and reduce inefficiencies.

- Safety Protocol Integration: Combine the sensor’s capabilities with broader safety measures for comprehensive risk management.

By focusing on these strategies, you can ensure the Yale Toss Sensor location GLP050VX enhances both safety and productivity.

Real-World Applications of the Yale Toss Sensor

The Yale Toss Sensor location GLP050VX has proven beneficial across multiple industries:

- Warehousing: Safely manage high stacks and avoid tipping accidents in storage facilities.

- Manufacturing: Ensure load stability during the transport of materials in busy production areas.

- Retail Distribution Centers: Prevent mishandling of goods in high-traffic settings.

- Construction: Handle heavy or uneven materials safely, even on challenging terrains.

In each of these scenarios, the Yale Toss Sensor location GLP050VX plays a critical role in preventing accidents and improving efficiency.

Frequently Asked Questions

1. Where is the Yale Toss Sensor located on the GLP050VX forklift?

The Yale Toss Sensor location GLP050VX is generally found near the mast or lifting mechanism to monitor fork alignment and load stability.

2. How does the sensor enhance safety?

The sensor provides real-time alerts based on tilt angles and load stability, allowing operators to make necessary adjustments.

3. What should I do if the sensor malfunctions?

Inspect the Yale Toss Sensor location GLP050VX for damage or debris and recalibrate if necessary. Contact a technician for advanced issues.

4. How often should the sensor be maintained?

Regular monthly inspections are recommended to keep the Yale Toss Sensor location GLP050VX in optimal working condition.

5. Can the sensor be added to older forklift models?

While primarily designed for specific models, retrofitting may be possible with additional modifications.

Conclusion: Enhancing Safety with the Yale Toss Sensor

The Yale Toss Sensor location GLP050VX is more than just a safety feature; it’s a transformative addition to any forklift. By understanding its location, functionality, and benefits, operators can ensure both safety and efficiency in their operations. Regular maintenance and proper usage of the Yale Toss Sensor location GLP050VX are key to optimizing performance and creating safer workplaces.

Investing in tools like the Yale Toss Sensor location GLP050VX demonstrates a commitment to advancing workplace safety and operational excellence.